Case Study: Low Outgassing Grease for Flat Panel Display

Application: Cross Arm Bearings

Location: Japan & South Korea

Challenge

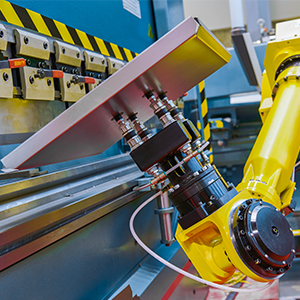

A semiconductor equipment manufacturer who specializes in automation and semiconductor production equipment approached us to find the right lubricant for their cross-arm robot bearings. These mechanisms, which manufacture flat panel displays, operate at high temperatures of up to 200°C under high vacuum. The manufacturer’s customer was having issues with outgassing contamination caused by a heritage lubricant. The customer needed a soft, low outgassing lubricant that would reduce contamination and improve wear performance.

- Can we provide a low outgassing, high-temperature, high-vacuum lubricant?

- Can we provide a soft grease for easy dispensing?

Solution

NYETORR® 6300S

A PTFE thickened, heavy viscosity, perfluoropolyether grease.

- Wide operating temperature of -75 to 250°C

- Extremely low vapor pressure and outgassing properties

- NLGI Grade 1

- Reduces friction to extend bearing life.

| Product | Chemistry | Temp Range (°C) |

Penetration Unworked Worked 60X |

Starting Torque (25°C) |

Running Torque (60 mins 25°C) |

|---|---|---|---|---|---|

| NYETORR 6300S | PFPE/PTFE | -75 to 250 | 315 321 |

147.5 g/cm | 74.7 g-cm |

Results

We provided the customer with a sample of NYETORR® 6300 which met their outgassing requirements but proved too stiff for their application. Our R&D team then formulated NYETORR® 6300S, a softer version of NYETORR® 6300 which was then tested and proven to have low outgassing properties and high penetration values for easy dispensing. NYETORR® 6300S reduced the customer’s risk of contamination and they remain satisfied with its performance.

Ready to learn more? Contact Us.