Electric Vehicles

The cars of tomorrow are designed today. That’s why our research and development team has been hard at work developing lubricant solutions for next-generation electric vehicles. The proliferation of EVs comes after policies have been put in place to ban internal combustion engine (ICE) vehicles in high traffic cities, cheaper batteries have become available, and the shift in cultural attitudes towards our environmental impact. According to a report by Bloomberg New Energy Finance, EVs are expected to make up 58% of new car sales worldwide by 2040.

What are the lubricant requirements for new electric vehicle designs?

EVs bring up a host of lubrication issues that must be addressed during the design stage. When components fail, it can put a driver’s safety and a manufacturers reputation at risk and discourage potential buyers from adopting new technology. While some general-purpose lubricants may no longer find a home in EVs, the increased technical challenges present in these designs require specialized synthetic lubricants to improve safety, reliability, comfort, and efficiency.

Light-weight synthetic hydrocarbon greases with advanced additive packages greatly reduce frictional torque between the gearing components. This allows for lower current draw over extended periods of use, which can improve engine efficiency and extend range.

If a connector loses signal, critical safety features such as braking, steering, ADAS or emerging autonomous systems could fail, with potentially fatal consequences. Grease acts as a protective barrier to prevent common causes of connector failure including wear, electrical short circuits, fretting and corrosion. To improve the reliability of your systems, a long-lasting grease that can withstand the operating conditions of your application should be selected.

Electric motors run at a higher temperature compared to ICE. A grease with excellent high and low temperature capabilities should be selected. A lubricant must be chemically stable at your high-temperature limit and have sufficient film strength to adequately prevent wear. At the lowest expected temperature, the lubricant must remain sufficiently fluid.

Plastic components are being used more frequently to reduce the total weight of EVs. It is important to select a lubricant that is compatible with all the materials in your assembly. Some lubricants can “attack” or degrade certain plastics and elastomers. Plastic compatible lubricants should be selected.

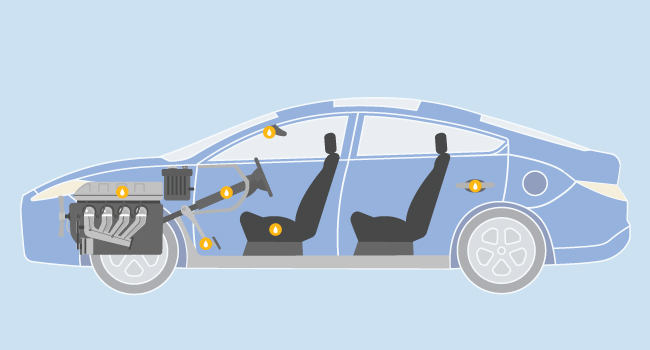

What Electric Vehicle Components Require Lubrication?

Below are just a few examples of applications in electric vehicles that can benefit from lubrication. Visit our Automotive Page to explore our full range of automotive solutions.

Want to learn more? Visit our Automotive Page or Contact Us.