Nye Lubeletter - April 2016

All About Additives – Extreme Pressure and Antiwear

All About Additives – Extreme Pressure and Antiwear

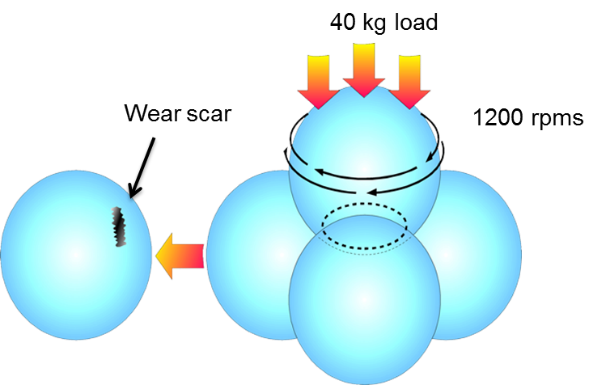

According to the Department of Mechanical Engineering at MIT, the wastage of resources resulting from high friction and wear is greater than 6% of the Gross National Product. There are several different types of mechanical wear mechanisms that can occur in a lubricating system, including adhesive wear, abrasive wear, pitting, and spalling. Wear preventative additives are a necessary component in lubricants that will be used in applications that are prone to such damage. Wear preventative additives fall into two categories: Extreme Pressure agents and Antiwear agents.

According to the Department of Mechanical Engineering at MIT, the wastage of resources resulting from high friction and wear is greater than 6% of the Gross National Product. There are several different types of mechanical wear mechanisms that can occur in a lubricating system, including adhesive wear, abrasive wear, pitting, and spalling. Wear preventative additives are a necessary component in lubricants that will be used in applications that are prone to such damage. Wear preventative additives fall into two categories: Extreme Pressure agents and Antiwear agents.

![]()

Lights, Camera, Nye!

Lights, Camera, Nye!

Nye was recently contacted by Boston Light & Sound, a national leader in entertainment technology, to provide a lubricant for a movie theater projector they were refurbishing. However, this projector was unlike any video projector used in today’s modern cinema.

Boston Light & Sound was asked to refurbish 70mm projectors for Quentin Tarantino's latest movie premiere, The Hateful Eight. The movie was shot using a lens system called "Ultra Panavision 70," technology that has not been used in Hollywood for over 2 decades. Boston Light & Sound used Rheolube® 716B to lubricate the internal components of the refurbished projector.

![]()

Lubricant Testing 101 - Penetration Tests

Lubricant Testing 101 - Penetration Tests

Penetration tests are conducted by Nye technicians in order to determine the stiffness of a grease and how a grease will react over time to service and wear. The higher the penetration value, the softer the grease. The lower the penetration value, the stiffer the grease. In some applications, a grease that is too stiff may not effectively migrate into areas that need to be lubricated. In contrast, a grease that is too soft may migrate away from the area that needs to be lubricated in an application. The P0, or unworked and P60 or worked penetration tests follow ASTM D-217 method for full scale or ASTM D-1403 method for half scale or quarter scale.

Penetration tests are conducted by Nye technicians in order to determine the stiffness of a grease and how a grease will react over time to service and wear. The higher the penetration value, the softer the grease. The lower the penetration value, the stiffer the grease. In some applications, a grease that is too stiff may not effectively migrate into areas that need to be lubricated. In contrast, a grease that is too soft may migrate away from the area that needs to be lubricated in an application. The P0, or unworked and P60 or worked penetration tests follow ASTM D-217 method for full scale or ASTM D-1403 method for half scale or quarter scale.

The second video in the Lubricant Testing series features the penetration tests. To learn how the test is performed on our lubricants, watch the video.

![]()

Why are Deviations Important for Nye?

Why are Deviations Important for Nye?

In today’s world, variables are all around us. Even the most robust of processes need to be flexible enough to handle environmental variables, raw material variables, and variations in equipment performance. As part of our process, Nye incorporates the flexibility of documenting subtle process changes when external variables that are beyond our control come into play. We create and record the changes we make to any process to ensure all organizational and stringent ISO standards are met. These changes are called deviations and can include everything from change in material color, hardware or software changes, methods of manufacturing (i.e. the number of passes through equipment) and testing parameters. The possibilities are endless.

In today’s world, variables are all around us. Even the most robust of processes need to be flexible enough to handle environmental variables, raw material variables, and variations in equipment performance. As part of our process, Nye incorporates the flexibility of documenting subtle process changes when external variables that are beyond our control come into play. We create and record the changes we make to any process to ensure all organizational and stringent ISO standards are met. These changes are called deviations and can include everything from change in material color, hardware or software changes, methods of manufacturing (i.e. the number of passes through equipment) and testing parameters. The possibilities are endless.

![]()