Nye Lubeletter - September 2006

SRV Speeds Customer Product Development

SRV Speeds Customer Product Development

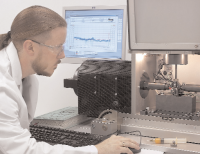

How can you be sure a lubricant will match your product’s projected life? Nye’s new SRV IV tribological test system may help. SRV is a German acronym for oscillation, friction, and wear. It was specifically designed for fundamental research in tribology, friction and wear analysis and is used in several ASTM and DIN test protocols. It can also simulate real world conditions to forecast how a lubricant will stand up to accelerate life testing. The SRV IV’s modeling capabilities can help troubleshoot existing applications and head off potential problems before life testing begins.

Antioxidants to Nanoparticles: Additive Studies Aim to Boost Lube Performance

Antioxidants to Nanoparticles: Additive Studies Aim to Boost Lube Performance

Nye is undertaking an intensive study of additives as a route to improving lubricant performance. Nye is now testing a new, patent-pending antioxidant, which the developer says survives temperatures up to 500ºC. In terms of a lubricant’s lifetime, antioxidants are among the most critical of grease additives. Nye is continuing tests to determine the optimal combination of oils, thickeners and the new antioxidant, which could be instrumental in formulating a new generation of high-temperature lubricants.

Get Smart About Grease

Get Smart About Grease

Even though 90% of commercially available additives are soluble in polyalphaolefin (PAO) oils, trade publications on occasion imply otherwise. While PAO’s solubility is not as robust as petroleum, less robust does not translate to poor or ineffective. Learn the facts about the use and strength of PAO oils verse petroleum.

Lab Cameras Offer Real Time Webcasts

Lab Cameras Offer Real Time Webcasts

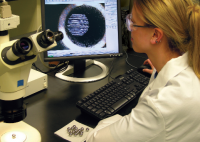

Now Nye’s lab is as close as your web browser. Nye recently installed Nikon digital cameras on lab microscopes for high resolution image capture and web-based viewing. Customers can log on and see exactly what a Nye lab technician is looking at in real time. Nye’s Director of Technology Joe Braza said, “The cameras enable a whole new level of cooperation and communication. We’ll be able to share results from tests as they happen.” By combining SRV data with microscope images, Nye can provide a complete picture for lubricant development and application trouble shooting. Rather than depending on verbal descriptions or emailed images, engineers and technicians can confer about a project “on the fly.”