NyeClean® 5057

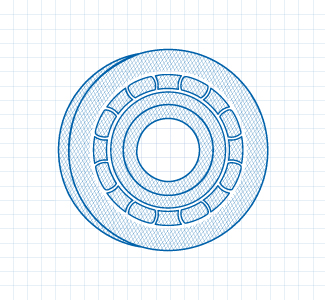

Semiconductor, clean-room, and in-vacuum manufacturing environments utilize robots for the handling and transfer of wafers, flat panel displays and other materials. Robots are often exposed to high vacuum, high temperature conditions, and are occasionally in contact with aggressive chemicals. These extreme conditions require a fluorinated lubricant to ensure the stable performance of the robots’ precision metal bearings. NyeClean® 5057 is a direct replacement for a recently discontinued semiconductor industry legacy grease.

Semiconductor, clean-room, and in-vacuum manufacturing environments utilize robots for the handling and transfer of wafers, flat panel displays and other materials. Robots are often exposed to high vacuum, high temperature conditions, and are occasionally in contact with aggressive chemicals. These extreme conditions require a fluorinated lubricant to ensure the stable performance of the robots’ precision metal bearings. NyeClean® 5057 is a direct replacement for a recently discontinued semiconductor industry legacy grease.

NyeClean® 5057 Advantages

- Complies with REACH PFOA regulations

- Reduces friction & wear

- Extends bearing life

- Offers minimal outgassing, particle generation, & vapor pressure

Lubricant Properties

| Properties | Test Conditions | NyeClean® 5057 | Test Method |

|---|---|---|---|

| Chemistry | - | PFPE / PTFE | - |

| Temperature Range | - | -50 to 250 °C | - |

| Kinematic Viscosity | 40 °C 100 °C |

192 cSt 35 cSt |

ASTM D445 |

| NLGI Grade | - | 2 | ASTM D1403 |

| Oil Separation | 24 h, 100°C | 6 wt% | ASTM D6184 |

| Evaporation | 24 h, 100°C | 0 wt% | CTM-01 |

| 4-Ball Wear | 1 h, 1200 rpm, 75°C | 20 kgf= 0.44 mm 40 kgf = 1.15 mm |

ASTM D2266 |

| Microscopic Particulate Contamination |

10-34 µm 35+ µm |

<250 particles/mL

|

FED-STD-791 Method 3005.4 |

| Knudsen Vapor Pressure | 150 °C 200 °C |

1.24E-08 Torr 2.66E-08 Torr |

CTM-59 |

Packaging Options

NyeClean® 5057 is available in a variety of packaging options. If your application requires a specific container, please contact us for custom packaging.

Want to learn more? Contact Us or Request a Quote