Protect Electrical Connections and Reduce Warranty Claims with Grease

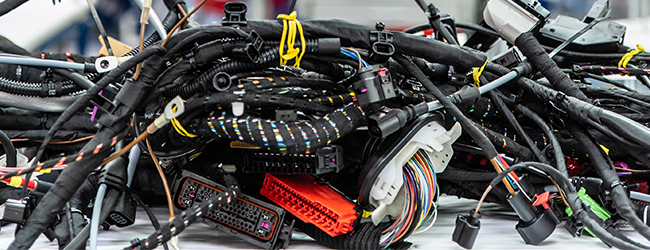

Modern machinery and vehicles – from cars to power tools, appliances to aerospace equipment – rely on an ever-increasing number of sensors and switches to operate properly and keep the driver or operator informed about equipment condition. Electrical connectors play a critical role in making all the components work properly. Connectors impact the operating life, performance and quality of countless electronic and electrical products. Unfortunately, every year many of those products fall victim to faulty connectors that interrupt operation and lead to component failure and increased warranty claims.

Equipment and automotive OEMs can reduce or eliminate most connector problems simply by applying the right lubricant to their contacts. Connector lubricants protect contacts from corrosion, fretting and wear to ensure long, trouble-free operation. They also reduce insertion force, improving production efficiency and reducing the potential for worker injury. Today, connector lubricants can be found in countless applications to ensure reliable operation long beyond the intended life of the equipment.

While connector failures are an issue in a variety of industries, nowhere is the proliferation of electrical sensors and components more apparent than in the automotive industry. The automotive industry represents one of the most challenging environments for electrical sensors and connectors.

Want to learn how connector grease reduces warranty claims? Download our whitepaper below to find out!

Related Technical Articles & White Papers

CONNECTORS: Protect Electrical Connections, Reduce Warranty Claims

This paper explains how lubricants restore connectivity to connectors in the field and prevents future failures from occurring. Electrical failures are a leading cause of recall claims.

Dr. Jason Galary

Read More