Rheolube® 462CF for Electric Power Steering

Engineers designing Electric Power Steering (EPS) systems have given themselves the ultimate challenge—operating at higher loads without overheating. Without proper lubrication, EPS systems generate a great deal of heat due to the sliding nature of the worm assembly. Lubricants reduce friction and heat generation so that these steering systems can operate at higher loads without system failure or reduced torque.

Nye is launching Rheolube® 462CF to enable next-generation EPS designs with focus on column and pinion gears. This light weight, low viscosity, synthetic hydrocarbon grease is fortified with an advanced additive package designed to greatly reduce low temperature torque and friction, while also providing wear protection and vibrational damping.

Temperature range

Operating temperatures have always been a concern in the automotive industry. Lubricants must work the same in the dead of winter and the peak of summer. Rheolube® 462CF has excellent low and high temperature performance, from -54 to 130°C, to conform with new demands from the automotive industry for vehicles to operate at temperatures below -40°, the previously held low temperature standard.

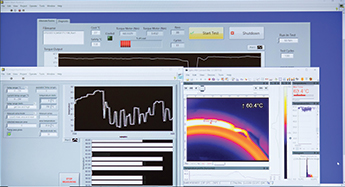

The picture above shows the heat distribution in a real EPS gear under similar driving conditions experienced in a car driving using Nye's advanced EPS test rig.

Torque

Along with its low temperature performance, Rheolube®462CF also exhibits good low temperature torque properties. At -40°C the grease has a starting torque of 428 grams per centimeter (g-cm) and a running torque of 153 g-cm outperforming current greases.

Plastic Compatibility

More automotive manufacturers are using plastic components as a cost-effective replacement for metal gears and other mechanisms. In EPS systems, it is not uncommon for there to be metal-on-plastic, plastic-on-plastic or plastic seals in contact with the grease. It is important to ensure that your lubricant is compatible with surrounding plastic materials. Rheolube® 462CF showed full compatibility against current EPS gear plastics.

Friction

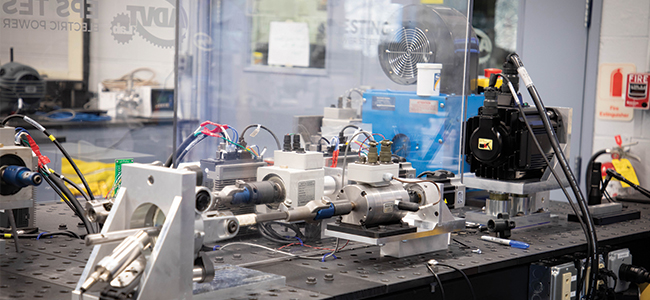

462CF was fortified with proprietary solid additives to ensure very low friction under various temperatures and load conditions. The grease was extensively tested on Nye’s new EPS test rig developed to simulate real test conditions used by many EPS manufacturers.

Nye's EPS test rig

Despite the fact that Rheolube® 462CF was developed with EPS applications in mind, the grease can also be used for other metal-on-plastic or plastic-on-plastic gear applications such as those found in starters, transmissions, and various other automotive mechanisms.

Ed Dykema – Regional Engineering Manager, Steering Systems

Ed Dykema – Regional Engineering Manager, Steering Systems

Ed has been with Nye for four years as one of our Regional Engineering Managers working out of our office in Troy, Michigan and specializes in identifying lubrication solutions for automotive steering systems. Additionally, Ed finds solutions for customers in all of our key markets including automotive, aerospace, power and utility, and consumer electronics markets. Prior to Nye, Ed has over 20 years of experience working as a Tier 1 automotive supplier in a variety of roles including Senior Design Engineer, Engineering Manager, and Program Manager. Ed holds a Bachelor of Science degree in Mechanical Engineering from Lawrence Technological University.

Ed has been with Nye for four years as one of our Regional Engineering Managers working out of our office in Troy, Michigan and specializes in identifying lubrication solutions for automotive steering systems. Additionally, Ed finds solutions for customers in all of our key markets including automotive, aerospace, power and utility, and consumer electronics markets. Prior to Nye, Ed has over 20 years of experience working as a Tier 1 automotive supplier in a variety of roles including Senior Design Engineer, Engineering Manager, and Program Manager. Ed holds a Bachelor of Science degree in Mechanical Engineering from Lawrence Technological University.

Click here to connect with Ed on LinkedIn.

Dr. Mihail Bancu- Strategic Market Innovation Manager

Mihail has been Nye for almost five years and works with the research and development team at Nye to develop new lubricants for next-generation technologies in the automotive, semicon, aerospace, and medical industries. Before coming to Nye, Mihail had 20 years of experience as a research and development chemist working in various fields of chemistry. Mihail holds a B.S. in Polymer Science and an M.S. in Chemical Engineering, as well as a Ph.D. in Organic Chemistry.

Mihail has been Nye for almost five years and works with the research and development team at Nye to develop new lubricants for next-generation technologies in the automotive, semicon, aerospace, and medical industries. Before coming to Nye, Mihail had 20 years of experience as a research and development chemist working in various fields of chemistry. Mihail holds a B.S. in Polymer Science and an M.S. in Chemical Engineering, as well as a Ph.D. in Organic Chemistry.

Click here to connect with Mihail on LinkedIn.