Design Engineer's Guide - Selecting a Gear Box Grease

Gear box performance has been consistently focused on mechanical efficiency, load handling capacity, and reliability. Recently, there have been additional demands to develop lighter weight, more durable and compact designs.

Gear boxes are often used for high-load, speed and temperature applications. Elevated speeds and loads often increase temperature, which can impact the life of the lubricant and ultimately the performance of the device. Many devices cannot utilize an oil bath to remove heat and wear debris; grease can provide the necessary lubrication to reduce friction and wear, extending the life of the gear box. Nye’s gear greases were designed to perform under these mechanically demanding conditions.

The advantages of lubricating gears and gear boxes

- Reduce Friction

- Decrease Gear Wear

- Improve Efficiency

- Extend Operational Life

- Control Temperature Rise

- Diminish Noise Emission

In addition to common metal gear applications, recent advances have allowed the use of lighter weight plastic gears for some applications. Plastic housings have also become more prevalent to support lighter weight design initiatives. Nye Lubricants has a complete line of synthetic, plastic compatible gear greases formulated specifically to address requirements for wear minimization under high-load conditions.

Applications that use gear box grease:

- Power Tools

- Industrial

- Outdoor Equipment

- Automotive

How to Select Your High-Performance Gear Grease.

Nye Lubricants has a complete line of high-performance gear greases designed specifically to address application requirements for gear lubrication, high-load operation, temperature limits and material compatibility. Most Nye gear greases are formulated with anti-wear, anti-corrosion, and extreme pressure additives.

Rheolube 380 & 380-G1

These PAO/Ester blend, Li Soap thickened greases are intended for high-speed metal gearing applications such as power tools and starter motors. Rheolube® 380-G1 is a softer grease that replenishes oil between gears but is more prone to leakage than Rheolube® 380.

Rheolube® 374A

Commonly referred to as Nye’s landing gear grease, Rheolube® 374A is recommended for metal gears that operate at low speeds under a wide temperature range.

Rheolube® 363AX-1

Rheolube® 363AX-1 is recommended for small gear trains. The grease offers excellent adhesion which helps it stay in place and useful on exposed gear trains.

Instrument Grease 794A

For appliance and other high-load, low-speed, metal gearing, Instrument Grease 794A is the recommended lubrication solution.

|

Lubricant |

Test |

Rheolube® |

Rheolube® |

Rheolube® |

Instrument Grease |

|

Base Oil |

- |

PAO/Ester |

PAO/Ester |

PAO |

PAO/Ester |

|

Temperature Range |

- |

-50 to 130° C |

-50 to 130 °C |

-50 to 125 °C |

-20 to 150°C |

|

Kinematic Viscosity |

40 °C |

34 cSt |

37 cSt |

41 cSt |

440 cSt |

|

Viscosity Index |

ASTM D-2270 |

137 |

130 |

145 |

105 |

|

NLGI Grade |

- |

2 |

1 |

2 |

2 |

|

Oil Separation |

24h, 100°C+ |

4.5% |

18.6% |

2% |

0.6% |

|

Plastic Gear Compatibility* |

- |

Better |

Better |

Better |

Better |

|

Plastic Housing Compatibility* |

- |

Fair* |

Fair* |

Better |

Fair* |

|

SRV OK Load |

ASTM D5706 |

1400 N |

800 N |

800 N |

350 N |

|

Load Wear Index |

ASTM D2596 |

34.8 |

35.6 |

31.9 |

27.6 |

*Esters are compatible with most plastic gear materials but may not be compatible with other plastics / elastomers. Nye offers Material Compatibility Testing

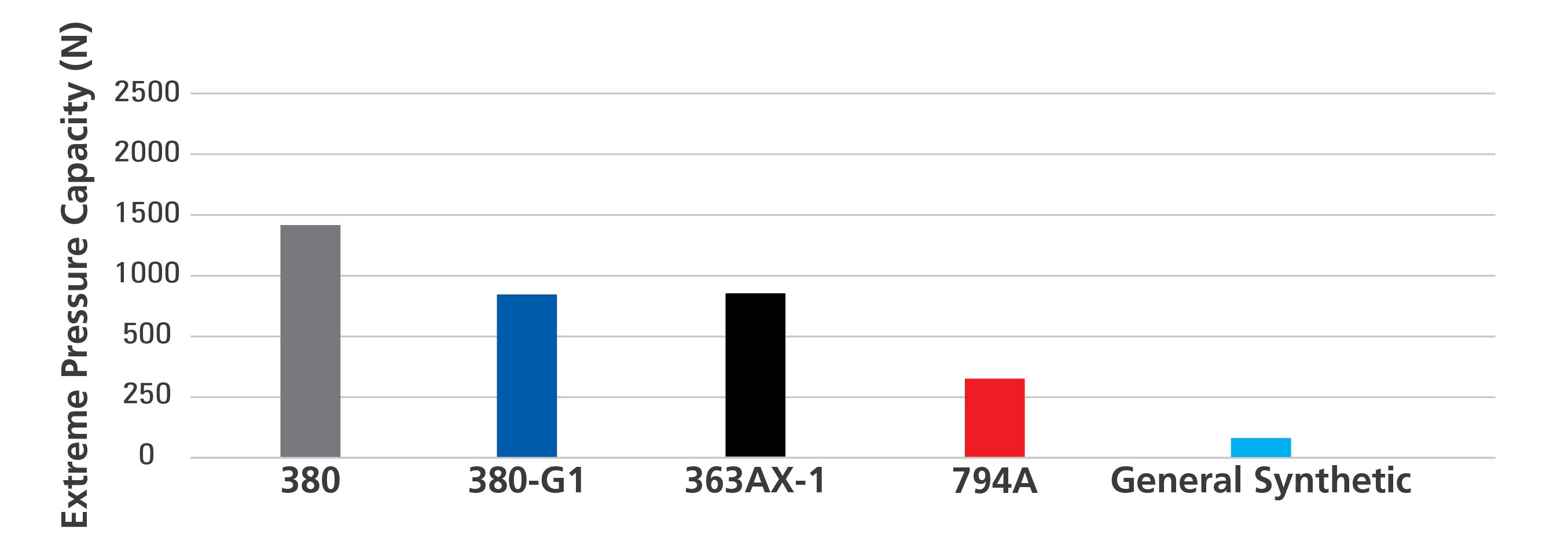

SRV OK Load

The SRV OK Load test measures a grease's ability to withstand extreme pressure. During the test, the test load is increased every 2 minutes until the specimens weld together, indicating lubricant failure. (Test Method: ASTM D5706)

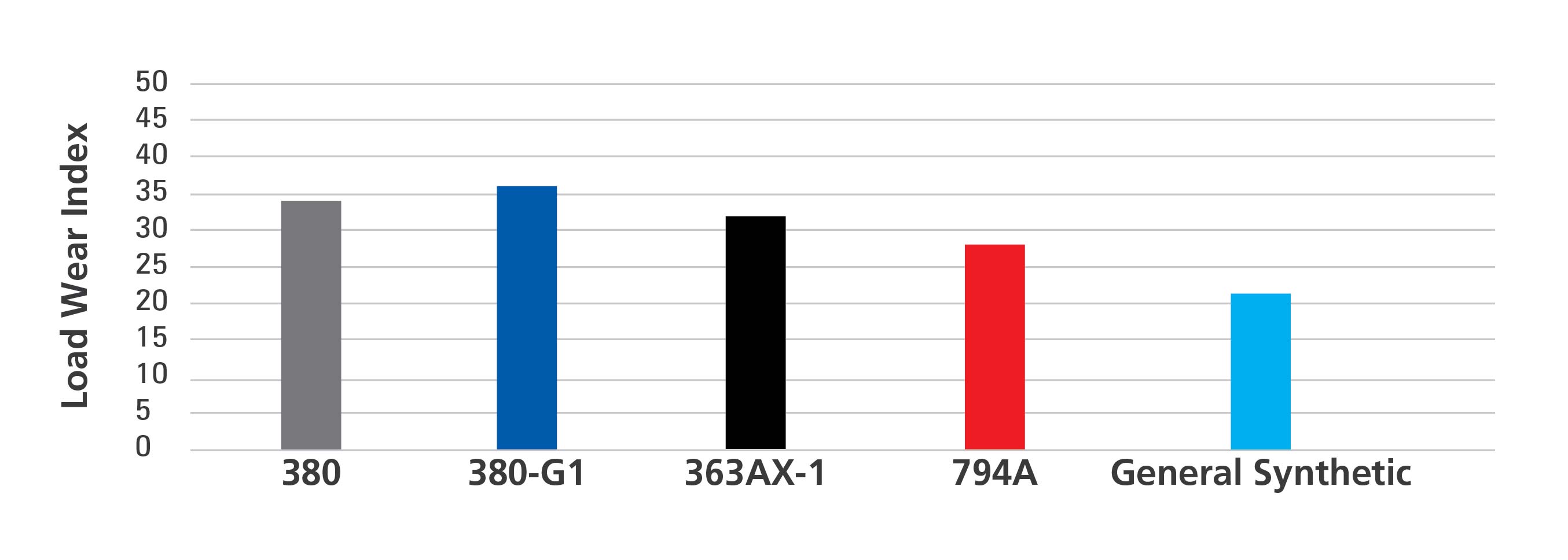

Load Wear Index

The Low Wear Index test creates an index of the ability for a lubricant to minimize wear at applied loads. It is based on a calculation of wear at non-seizure loads on the way to determining the weld point. (Test Method: ASTM D2596)

Gear Box Case Studies

Our case studies will give you an inside look at Nye success stories that showcase our engineering and testing capabilities. Learn more about how we help solve some of our customers' most difficult challenges throughout their development and design processes.