Case Study: Competitive Lubricant Pricing for Corrugator Bearings

Background

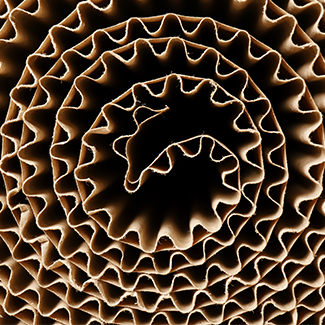

Corrugating and pressure roll bearings operate at high loads and temperatures which exposes the bearings to increased wear. An American corrugating company that supplies paper and packaging solutions approached Nye because they were exploring new grease options to use within their corrugating roll and pressure roll bearings to prevent wear.

Challenge

- Nye’s lubricant must protect bearings at a lower price than competitor lubricants.

Solution

NyeCorr® 140

A PTFE thickened, heavy viscosity, completely fluorinated, PFPE grease.

- Perfect for severe service bearings

- Excellent high temperature performance of up to 250°C

- NSF H1 food grade registered for incidental food contact

- Resists common solvents

- Rust-inhibited

| Product | Chemistry | Temp Range (°C) | Oil Separation (24 hrs @ 100°C) | Evaporation (24 hrs @ 100°C) |

|---|---|---|---|---|

| NYECORR 140 | PFPE / PTFE | -20 to 250 | 4.1% | 0% |

Results

The customer decided to switch to NyeCorr® 140 as the primary grease for their corrugating roll and pressure roll bearings. This PFOA-free grease offered the company substantial cost savings without experiencing any drop offs in performance or lubricant service intervals.

Ready to learn more? Contact Us.