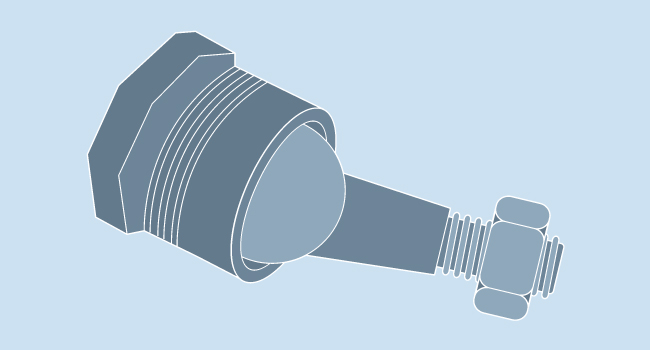

Ball Joints

An efficient ball joint design plays a critical role in ensuring a smooth driving experience. Tight-fitting, ball-and-socket designs are subject to dynamic motion in almost every direction and must be protected against wear. Ball joints are exposed to a variety of operating conditions including extreme environmental exposure, engine heat, jolts on rough surfaces, and continuous micro-motion on smooth roads.

Why Do Ball Joints Need Grease?

Grease provides smooth action for ball joints to operate efficiently and protect against wear. Packaging of ball joints, depending on vehicle design, may place it close to hot engine components where it needs to resist breakdown due to heat. In addition, a ball joint must operate quietly, even after a vehicle has been motionless for long periods of time. Grease also provides protection from environmental conditions to protect components and provide a ‘lube for life’ solution. The right lubricant will:

- Reduce friction and wear

- Extend ball joint life

- Meet and exceed lifetime durability requirements

- Operate quietly with no stick slip

- Be compatible with boot material

- Have excellent low temperature torque

- Resist water spray-off

What is the Best Ball Joint Grease?

Contemporary ball joints are designed without grease fittings, so it is important to select the right lubricant as the initial fill must provide lifetime lubrication. Wide temperature, water and salt water resistant synthetic greases meet these demanding requirements.

Fluorocarbon Gel 880: Grease for Ball Joints

Nye’s Fluorocarbon Gel 880 is a PTFE-thickened, heavy viscosity dimethyl silicone grease with excellent water resistance and structural stability under a wide temperature range and is our recommended solution for most ball joint applications.

| Properties | Test Conditions | Fluorocarbon Gel 880 | Test Method |

|---|---|---|---|

| Chemistry | - | Dimethyl Silicone/PTFE | - |

| Service Temperature Range | - | -40 to 200 °C | - |

| Kinematic Viscosity | 100 °C | 7349 cSt | ASTM D-445 |

| Kinematic Viscosity | 40 °C | 18407 cSt | ASTM D-445 |

| NLGI Grade | - | 2 | ASTM D-217 |

| Oil Separation | 24 hours, 100 °C | 0 % | ASTM D-6184 |

| Evaporation | 24 hours, 121 °C | 0.06 % | NYE CTM |

*Nye Company Test Method

Want to learn more? Contact Us.