Electrical Components

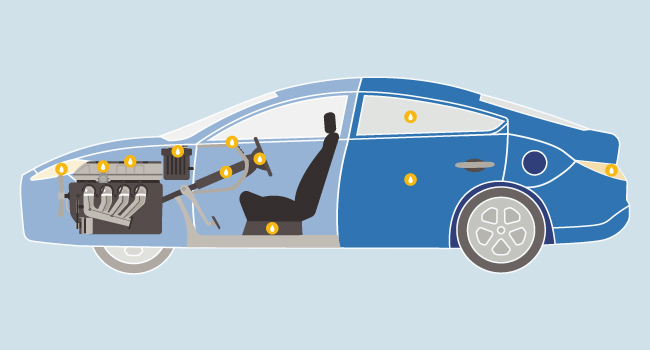

With the proliferation of electronic controls and development of autonomous and electric vehicles, there are more connectors and sensors in a vehicle than ever before. Each connection is a potential failure point which can be fatal in safety critical applications. Other failures can significantly impact the quality of your vehicle and result in recall claims.

Specialty lubricants for connectors and sensors ensure long lasting connections to improve the reliability of your automotive systems.

Connector lubricants are used to prevent wear, environmental corrosion. They are also very effective at preventing fretting corrosion, the result of micro-motions between contacts caused by vibration and thermal changes within the connector housing. By reducing the formation of metal oxide at the mated interface, connector greases extend contact life and keep resistance low.

High insertion force has become a major assembly challenge. Mating multi-pin connectors, sometimes in hard to reach locations, often requires significant force – creating the potential for incomplete mating, as well as repetitive-motion injuries for assembly workers. Synthetic based lubricants have been proven to reduce high insertion forces – without unacceptable increases in resistance.

NyoGel® 760G is the industry leading connector grease trusted and approved by leading OEMs for a variety of connectors including:

- Seats

- Doors and Windows

- Tail lights

- Trailer Tows

- Dashboard Switches

- And more.

NyoGel® 760G Specifications

NyoGel® 760G is specified by many leading OEMs in the Automotive industry.

- Toyota: TSK2525G-A-NY17

- Ford: WSB-M1C239-A

- General Motors: 9986087, 12377900, 1645644

- FCA: MS-9469, 04661991, 05013781AA

- Daimler Truck, Freightliner: 48-02439-002, 002V/YNA, CPP760G

The accuracy and operating life of automotive sensors is directly related to the quality of the lubricant used on both sensitive electrical and mechanical components. To meet a broad range of design needs, Nye offers light, low-shear sensor greases for very low power applications; lubricants with exceptional film strength to accommodate heat generated by resistance; and unique underhood sensor lubricants that withstand years of vibration, thermal cycling, temperature extremes, as well as salt spray, sand, road grit, and underhood fluids.

When electromechanical sensors or potentiometers break contact, signal is lost. To ensure continuous contact, choose a low-viscosity fluorinated lubricant. A more viscous lubricant may cause the contact to hydroplane, instead of remaining in contact with the resistor.

Powertrain

EGR temperature sensor - Rheotemp™ 768G

Air Management

Bearings in throttle position sensors - Uniflor™ 8922EL

Throttle position sensor - Uniflor™ 8950

Steering

Column Steering angle position sensor - NyoGel® 741A-RED & Fluorocarbon Gel 885

Designed to meet the 3X life standard, Nye switch lubricants are available for tin, copper, brass, and noble metal contacts. Tailored to low, medium, or high current switches and formulated for light, medium or heavy loads, these lubricants guard against millivolt drop, open circuit resistance problems, and "-40 °C contact bounce." Underhood, they withstand thermal cycling and temperature extremes, from –90 to 250 °C and resist humidity, dust, water, salt water, fuel, and underhood fluids. For the mechanical parts of a switch, Nye's family of damping greases provide an economical way to control the sound and feel. Air conditioning and climate control systems rely upon a series of motorized vents to route airflow for the comfort of the driver and passenger. Greases for this application should be formulated specifically to work with plastic gears and offer reliable performance at low temperatures.

Seats

Switches - Rheolube® 362F & Uniflor™ 8512

Doors & Windows

Switches - Instrument Grease 732C

Dashboard Switches

Audio switches & Radio knobs - NyoGel® 774F

Headlight switch - NyoGel® 774VH & NyoGel® 774L

HVAC controls - NyoGel® 774HF

Terminals & connectors - NyoGel® 760G

Steering Column

Ignition switch - Rheolube® 362

Lubricants for Electrical Automotive Components

| Product | Chemistry (Base Oil / Thickener) | Temp. Range | Product Description | Application Notes |

|---|---|---|---|---|

|

FLUOROCARBON GEL 885 |

Dimethyl Silicone/PTFE | -40 to 200°C | A heavy viscosity grease for low friction applications. | Steering angle position sensor |

|

INSTRUMENT GREASE 732C |

Clay/Ester | -54 to 150°C | A light viscosity grease. Benefits include salt water resistance. | Door & Window Switches |

|

NYOGEL 741A-RED |

Phenylmethyl Silicone/Lithium Soap | -65 to 200°C | A medium viscosity grease. Benefits include superior performance for light to moderately loaded instruments operating at low temperatures where little torque is available. | Steering angle position sensor |

|

NYOGEL 760G |

PAO/Silica | -40 to 135°C | A medium viscosity grease. Benefits include good water resistance. | Terminals & connectors |

|

NYOGEL 774F |

PAO/Silica | -30 to 120°C | A stiff, medium viscosity, grease. Benefits include light damping, good water resistance, enhanced lubricity and noise damping | Audio switches & Radio knobs |

|

NYOGEL 774L |

PAO/Silica | -40 to 120°C | A light viscosity grease. Benefits include light damping and good water resistance. | Headlight switch |

|

NYOGEL 774VH |

PAO/Silica | -10 to 120°C | A stiff, very heavy viscosity, grease. Benefits include heavy damping and good water resistance. | Headlight switch |

|

RHEOLUBE 362 |

PAO/Lithium Soap | -54 to 125°C | A grease designed for bearings, sliding surfaces, gear trains and electrical components. | Steering column ignition switch |

|

RHEOLUBE 362F |

PAO/Lithium Soap | -54 to 125°C | A light viscosity grease. Benefits include excellent low temperature performance. | Seat switches |

|

RHEOTEMP 768G |

PAO-AN/Urea | -40 to 175°C | A medium viscosity grease. Benefits include high temperature performance and insertion force reduction. | EGR temperature sensor |

|

UNIFLOR 8512 |

PFPE/PTFE | -50 to 225°C | A medium viscosity grease. Benefits include resistance to fuels and aggressive chemicals, excellent thermo-oxidative stability and low vapor pressure. | Seat switches |

|

UNIFLOR 8950 |

PFPE | -90 to 225°C | A light viscosity oil. Benefits include excellent oxidation resistance, excellent plastic and elastomer compatibility and resistance to aggressive chemicals. | Throttle position sensor |

|

NYOGEL 774HF |

PAO/Silica | -30 to 120°C | A heavy viscosity grease. Benefits include a heavy damping, water resistance, enhanced lubricity and noise damping | HVAC controls |