Nye LubeLetter - August 2017

Improving Suspension with the Right Lubricant

A strut is an integral part of a vehicle’s suspension, supporting the vehicle while also absorbing impacts from bumps, potholes, and other road disturbances. Lubricating the upper isolator, jounce bumper and utilizing the correct internal strut/shock oil will help reduce friction, noise, vibration, and harshness (NVH) in the suspension. Nye has proven success lubricating all three of these strut components, and can suggest the ideal grease or oil for your design requirements.

A strut is an integral part of a vehicle’s suspension, supporting the vehicle while also absorbing impacts from bumps, potholes, and other road disturbances. Lubricating the upper isolator, jounce bumper and utilizing the correct internal strut/shock oil will help reduce friction, noise, vibration, and harshness (NVH) in the suspension. Nye has proven success lubricating all three of these strut components, and can suggest the ideal grease or oil for your design requirements.

![]()

NASA, the NOAA, and Nye

NASA, the NOAA, and Nye

For over 60 years, we have been involved with leaders in the aerospace industry, like NASA, designing and testing lubricants for space applications. Our latest partnership was on next generation geostationary weather satellites, called the GOES-R series. According to the Goes-R Website affiliated with NASA and the U.S. National Oceanic and Atmospheric Administration (NOAA), “The satellites will provide advanced imaging with increased spatial resolution and faster coverage for more accurate forecasts, real-time mapping of lightning activity, and improved monitoring of solar activity.” Nye was involved in lubricating both the reaction wheels and solar array drives within the GOES-16 launched in November 2016. Download our Brochure to see which lubricants are taking off with the next-generation of spacecraft.

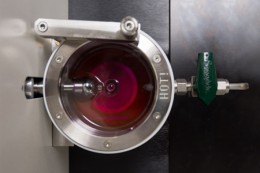

Semicon & In Vacuum - Industry Lubricants

![]() Today’s vast array of electromechanical devices in semiconductor wafer fabrication, flat panel, solar panel and LCD manufacturing equipment place increasingly challenging demands on their lubricants. Semicon & In Vacuum Industry lubricants must be able to extend component operating life, and improve productivity, while minimizing particle generation and outgassing that can contaminate wafers and high-speed inspection systems. Watch our Semicon Industry video to learn more how Nye is servicing this industry through our lubricant testing, application expertise, and product offerings.

Today’s vast array of electromechanical devices in semiconductor wafer fabrication, flat panel, solar panel and LCD manufacturing equipment place increasingly challenging demands on their lubricants. Semicon & In Vacuum Industry lubricants must be able to extend component operating life, and improve productivity, while minimizing particle generation and outgassing that can contaminate wafers and high-speed inspection systems. Watch our Semicon Industry video to learn more how Nye is servicing this industry through our lubricant testing, application expertise, and product offerings.

![]()

Mini Traction Machine Comes to Nye

Mini Traction Machine Comes to Nye

Nye’s Applied Science and Tribology Lab (ASTL) has continued to expand its capabilities in testing and characterization of tribological applications with the acquisition of a Mini Traction Machine (MTM). The MTM is very different from conventional tribometers like a 4-Ball or SRV, as it measures frictional properties in a wide variety of rolling/sliding conditions. This is critical to simulating applications like rolling element bearings and gears. Through the flexibility of the MTM, very complex tribological tests can be performed on range of materials, from metals and plastics to soft contacts.

Nye’s Applied Science and Tribology Lab (ASTL) has continued to expand its capabilities in testing and characterization of tribological applications with the acquisition of a Mini Traction Machine (MTM). The MTM is very different from conventional tribometers like a 4-Ball or SRV, as it measures frictional properties in a wide variety of rolling/sliding conditions. This is critical to simulating applications like rolling element bearings and gears. Through the flexibility of the MTM, very complex tribological tests can be performed on range of materials, from metals and plastics to soft contacts.