Protect Optics with Low Outgassing Space Lubricants

What is Outgassing?

All materials, including lubricants, outgas to some degree, and outgassing is akin to evaporation; it is the release of smaller fractional molecules from the bulk liquid or solid material. Outgassing is the cause of “that new car smell” as the plastic and elastomeric materials on the interior of a new car give off vapors from the freshly fabricated materials such as the door panels, seats, carpet, and seals.

How Does Outgassing Effect Lubricant Life?

Lubricants typically operate under pressurized atmospheric conditions where evaporation losses can compromise a lubricant's integrity over time, and these evaporation losses are accelerated when operating in vacuum. Lubricants with lower outgassing means a lower loss of lubricant material over time, resulting in longer lubricant operating life and lower material loss.

How Does Lubricant Outgassing Affect Optics?

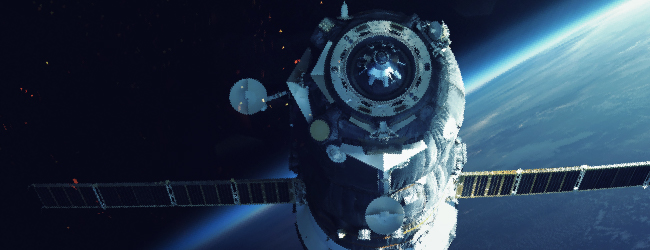

In a situation where an outgassed molecule becomes airborne, it can condense on a surface and care must be taken that the condensate does not adversely affect the optical or surface properties of the material onto which it condenses. For example, our low outgassing lubricants are recommended for satellite mechanisms near the camera lense to prevent an image from becoming compromised during operation.

How is Outgassing Measured?

For these reasons, extreme care should be taken to ensure the lubricants selected offer the lowest outgassing possible. Low outgassing lubricants are created by stripping a lubricant in a thermal chamber under vacuum to remove the unwanted outgas constituents.

Nye outgassing testing (per ASTM E595 Vacuum Stability) is designed to screen materials for volatile contamination. This test provides percent Total Mass Loss (TML) and percent Collected Volatile Condensable Materials (CVCM) data for our lubricants. Nye engineers can monitor the outgassing via Residual Gas Analysis to determine the elemental species contained in the outgassing material. This testing provides customers with a better understanding of the stability of our materials in a static vacuum environment and the ability to identify what materials are outgassing. Additionally, this test can show how much of the outgassing is condensable to give an indication of the lubricant’s material suitability within sensitive mechanisms in a vacuum environment.

Nye’s Low Outgassing Lubricants for Space Applications

NyeTorr® and MAC-based products are specialty lubricants formulated specifically for space mechanisms. These low outgassing lubricants are long-lasting, offer advanced wear protection, and can withstand the vacuum of space.

Visit our Space page to learn more about our lubricants for these applications.