Fight Fretting with Rheotemp™ 769G

Prevent Fretting

We all tend to fret when things get rough, but fretting has more serious consequences in electrical connector applications. Fretting corrosion and wear in electrical connectors and contacts is the result of micromotion caused by vibration and/or thermal expansion due to heating or cooling cycles. These micromovements result in wear down through the metal coatings into the base material that then becomes oxidized, eventually creating an open connection and ultimately, power failure or signal loss.

As this oxide layer builds up and increases, the oxide film acts as an insulator between the contacts which creates an open circuit resulting in voltage drop across the terminal. The loss of continuity across the connectors can be catastrophic as it can affect airbags from properly deploying or loss of braking and steering systems which could result in loss of life.

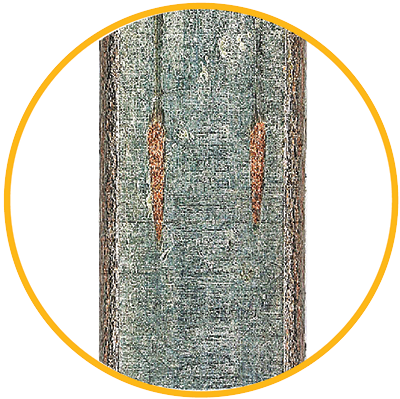

Fretting Wear:

The Nye test monitors fretting cycles (micromotion) of terminals until resistance increases 100 milliohms over the static baseline, to predict the life of terminals.

Rheotemp™ 769G

18.7MM cycles

Unlubricated

0.5MM cycles

Test Conditions: 2.8mm APEX Copper-Tin Terminals, 10Hz, 100 microns, 50% Failure Cycles

To minimize wear and keep oxidation at bay, the implementation of a dielectric grease is key. Dielectric grease has two primary benefits.

- First, the grease reduces physical wear between the connecting surfaces as they undergo micromotions and fretting wear. This helps to preserve the layered coatings on the connectors, designed to prevent oxidation and minimize resistance.

- Secondly, they insulate the system from the surrounding environment, preventing the build-up of insulative oxide layers which are ultimately responsible for resistance increase and signal loss.

Non-Conductive

Although Nye’s dielectric lubricants are non-conductive, they still allow the microscopic asperities of the contacts to transfer signal and power, while filling in the valleys of the connectors, where oxides and wear debris can form. The dielectric properties become especially important in multi-pin connectors, eliminating the possibility of a short between pins. As connectors and electrical systems evolve and become more sensitive to resistance changes, dielectric lubricants must also progress to keep up with the demanding needs of these applications.

Nye recently released Rheotemp™ 769G, a polyurea thickened, medium viscosity, synthetic hydrocarbon grease specially fortified for advanced fretting protection. In fact, Rheotemp™ 769G offers three times the fretting protection over our general-purpose electrical connector greases.

Reduces Insertion Force

Rheotemp™ 769G also significantly lowers the insertion force required to mate connectors, protects against environmental corrosion, and has excellent thermal stability and water washout characteristics. Insertion force is a frequent problem faced by those who manufacturer large multi-pin connectors and wire harnesses. These connectors require greater amounts of force to mate the connections which increases the risk of musculoskeletal disorders in assembly technicians.

Dielectric grease reduces the amount of force required to mate connectors by lowering friction between the two sides of the connectors. Lower insertion force reduces the amount of physical strain put on assembly line workers which can help reduce worker compensation claims.

Another benefit of using dielectric grease in connectors is that is creates an environmental seal to keep out water, dirt, and other corrosive elements that can lead to power failure. Applying grease during production ensures a solid connection for the life of the terminal.

Nye has a long history in formulating universal standard, OEM-trusted, dielectric greases for connector applications. Whether it’s in your car, boat, plane, or truck, our grease can help you fight fretting corrosion to improve your products reliability.